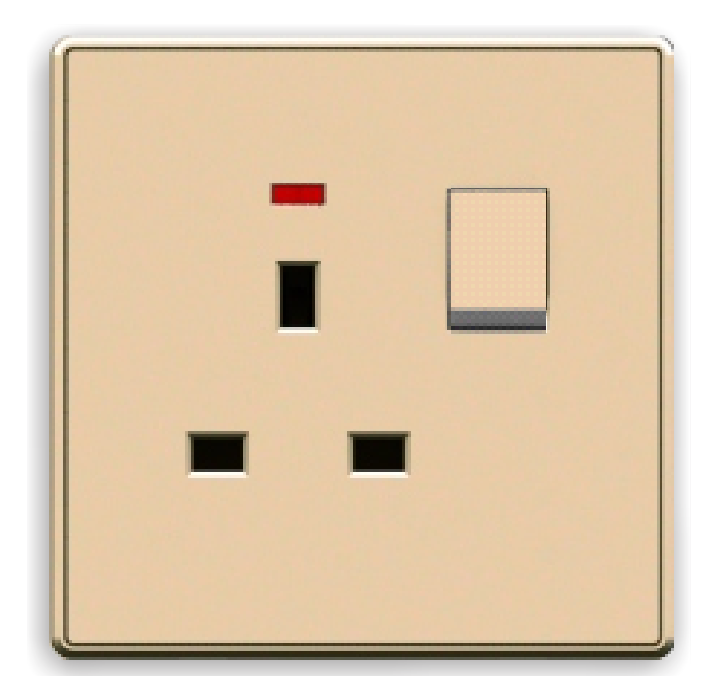

now the SWITCH SOCKET infect our home life even the safty . so we need pay attention on the quality of them . Thorough evaluation of switch quality and full solution of internal structure. The three core parts of the switch (copper, flame retardant rear seat, rocker and support head) are tested:

Switch socket quality identification

A: Good or bad choice of copper:

1, in the same material under the circumstances to see the length of copper, the longer the better (because the copper length determines the size of the socket distance, the wider the jack spacing two or three insert at the same time more convenient to insert). The length of the copper below is fairly good. Some copper pieces are less than 4.5 in length.

2. The thicker the thickness of the copper sheet, the better. (The longer the socket life is, the longer the elasticity of the copper sheet is.)

3, to see if the copper sheet is a formed copper sheet into the picture (you can clearly see the following picture of the whole piece of copper sheet material is exactly the same, without any riveting points)

Old-fashioned riveted copper sheet (obviously you can see that the two materials are completely different from the bridge material, and there are obvious riveting points):

One-time molding is always better than the old riveted copper sheet, because the once-formed copper sheet is always smaller than the riveted resistance, the relative heat is smaller, the elasticity is better, the higher the safety factor is, the higher the conductivity is). The wires in the house renovation line are the same, the difference between a complete wire and a knotted wire.

4 Contact method of socket copper sheet and plug conductive sheet:

A: point contact:

B: Face contact:

The use of surface contact is always more conductive and safe than point contact (point-to-point contact is easier to generate sparks and copper is easier to loosen)

B: The choice of flame retardant rear seat:

1. Burn the back seat with a lighter. The smaller the better, the better the safety.

3, melt only the best not to burn.

3, the smaller the odor the better, the sooner the odor disappears, the better. (less harmful substances)

C: Selection of rocker and support head:

1, strong spring support head is always better than plastic head support (because the plastic head will wear after the support of the lubricant, will cause the switch is not flexible and stuck (slip) phenomenon.

2. The bigger the rocker, the better (because the larger the rocker, the better the heat dissipation)

3, rocker full silver plating is always better than some silver plating and silver plating at all (since the conductivity of silver is always stronger than copper)

4, see the size of rocker contacts (of course, the material is more important, but as the general owner to see the material is not visible, this is not to say) the larger the contact the better (the red circle below the place).

All of the above is a comparison of the first-line high-quality switches. The other two-wire quality switches are a bit wasteful with this comparison method. Only one of them can be used.

The detection of the panel material can be bent by hand. If there is a continuous bending, we need choose the PC material not the ABS.